After last weeks post covering the modification of a Commodore datasette drive to create cassette masters, literally no one asked for more details on how the datasette drive was powered. So I thought that was a perfect excuse to go into considerably more detail on the subject.

The datasette was first introduced to go with the Commodore PET in 1977, and remained in use right through into the early 1990s. The original PET was almost entirely 5V. All the logic, ROM and RAM was 5V only. These were the days before the 4116 DRAM chips which need -5V and +12V as well.

The exception to the 5V only statement is the datasette drive. It has a 5V supply for the internal logic, but there is a separate power connection for the motor, which should be supplied with 6V.

The arrangement is different from most cassette mechanisms. Normally there would be a permanent 6V supply for the motor, and a mechanical switch on the drive itself to turn the motor on or off, sometimes in series with a relay controlled switch on the computer end. The Commodore datasette relies on the host to use the sense line to detect when a key is pressed on the mechanism to turn the motor on or off.

You will see some situations where these are driven from 5V, for example the old parallel port X1531 type transfer cables. These run the motor slowly, 5/6 of normal speed. This makes the tape move more slowly, so the data is written closer together on the tape. When played back at normal speed, it will actually be 20% fast. This is just about within the tolerance of the loading routine, so can speed up loading a bit, but it's not guaranteed, and wouldn't be recommended these days.

PET 2001

The PET's power supply was 9V DC unregulated, with several 7805 5V regulators, so 9V was available, and that was used to generate 6V for the motor.

There is quite a lot going on there. If you ignore the resistors and 2N3904 on the left, what you have is a 7.2V zener diode fed via a 1.5KΩ resistor, which gives a regulated 7.2V reference. The 10nF capacitor smooths the reference voltage, which is then buffered by the two transistors in a darlington arrangement. The output is a regulated supply of 7.2V, minus the two base voltage drops, 0.6V each, giving a 6V supply.

Bringing back the 2N3904, when the Control signal is low, the 2N3904 is off, and does nothing, and the output voltage remains at 6V. When the control signal is high, the transistor is turned on and pulls the 7.2V reference voltage down, and in turn, the output transistors are turned off and there is no output.

That gives a simple switched 6V output. Control is high, motor is off. Control is low, motor is on.

VIC20 / C64 / C128 / TED

Over the years, that circuit was revised a few times, and I found quite a bit of variation from model to model and machine to machine. Different drive transistors, different zeners etc. The voltage is always "around 6V", but it varies from a little over 5V to almost 7V on some of the machines I have tested.

The final version in the TED machines like the C16 and plus/4 was much simplified.

This used a 7406 gate to replace the 2N3904 transistor, but still doing the same job of pulling down the reference voltage when the drive is not in use. Gone is the second buffer transistor, so more current is drawn from the zener reference, which had it's resistor value dropped to 470Ω. That does mean that when the motor is off, the 470Ω resistor is across the supply rails and wasting 20mA all the time.

Mini PET

When I designed the original Mini PET, I used the design from the TED machines shown above.

The two datasette drive circuits were drawing 40mA in total, with the rest of the board drawing less than 100mA, but it was nice and simple and a product of the last generation of Commodore optimisation.

Mini PET 40/80

When it came to the Mini PET 40/80, there was an additional challenge to deal with, soft power on/off. I could have stuck with the same circuit, but the 40mA draw would have been present when the rest of the unit was switched off, not ideal. I could have added a separate transistor, probably a MOSFET, to switch the 9V rail before this circuit, but I was trying to simplify things.

I had used some new surface mount 6V regulators with on/off controls in the multi port duplicators I had made for TFW8b. Each drive had it's own switched and regulated supply, which worked quite nicely. I was able to use the sense input directly to switch them on or off, so no additional logic was required, not even a pullup resistor.

I would have like to use those, but they were only available in surface mount, or the sort of 5 pin TO220 packages that might be a problem for some kit builders as the leads are a bit close together.

After looking around for quite a while for alternatives, I finally settled on the Micrel MIC2951. (Micrel is now owned by Microchip, but I haven't seen any Microchip branded as yet.)

This little 8 pin chips work in two modes. In the first mode, they are fixed 5V, 150mA regulators, with a shutdown input so they can be turned on or off via the soft power on controls.

The Mini PET uses less than 100mA, so 150mA should be fine. I used a second 5V regulator to supply the datasette port, more than enough for a datasette drive logic and powering an SD2PET.

The second mode allows the voltage to be set via a resistor divider (like an LM317 if you remember those). The shutdown signal is the same logic as the datasette control, low is on, high is off. A 74LS07 gate is used to pull the signal low when the motor should be on, the rest of the time, the 10KΩ resistor pulls it high and keeps the output turned off.

The value is set using the following equation, Vref is an internal 1.235V reference, and R2 is using the recommended value of 100KΩ. The nearest standard resistor value to give the output voltage we need is 390KΩ.

That gives an output voltage of around 6.05V. The value depends on the resistors which have a 5% tolerance (absolute worst case 5.59V-6.56V). The exact value is not important, as long as the voltage is within range and is constant during playback. Speed was expect to vary over the life of the drive due to belt stretching, so is accounted for in software (by timing the header tone at the start). The output is current limited to 150mA, to avoid motor burnout when rewinding or fast forward is left pressed and the end of the tape is reached.

That left the power section of the Mini PET 40/80 as four identical MIC2951 chips, and a pile of passive components.

Mini PET 40/80D

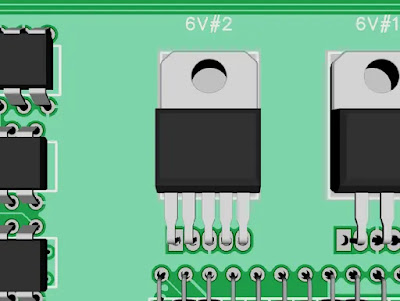

When it came to the Mini PET 40/80D, I was able to go for one of the surface mount 6V regulators with enable pins, so no need for the resistors, these were pre-set for 6V. The 5V regulator next to them is a plain fixed voltage always on type, as there was no need for soft power on with the 40/80D.

The on/off pin was now the inverse logic, so I needed to use 74LS06 dates to drive those, but it at least there were no zeners or set resistors.

Advertisements

The Mini PET 40/80D is still available from TFW8b (whilst stocks last)

https://www.thefuturewas8bit.com/shop/tynemouth-products/minipet4080d.html