I like things nice and bright when I am working. I have a three way light fitting in the workshop ceiling, and had been using standard candle bulbs.

I was looking around in .....checks jungle website history..... 2021 and found these listed as "LED Corn Bulbs 26W 200W Equivalent".

They looked like they would do the job, so I ordered the pack of three bulbs.

And wow, they are bright.

The corn cob bulbs sort of fitted with the flowery light shades left there by the previous owner. Bit of a hint of Day of the Triffids. But the important bit was the workshop was lit up like an operating theatre.

Those are on about 18 hours a day, 365 days a year, and they lasted about two years before the first one failed.

Not bad, I'll take that for about £5 a bulb. At the time, I just ordered another pack of three and replaced the dead one.

I am sure you know I am not the sort of person who throws anything away, so I had kept the dead bulb "in case they came in handy one day".

They are made from a series of surface mount LEDs, and I couldn't see any that had gone black, which would indicate an bad LED. With LED bulbs like that, you know it's probably bad electrolytic capacitors. But you also know they are sealed, and you can never get them back together again, so no way to repair them.

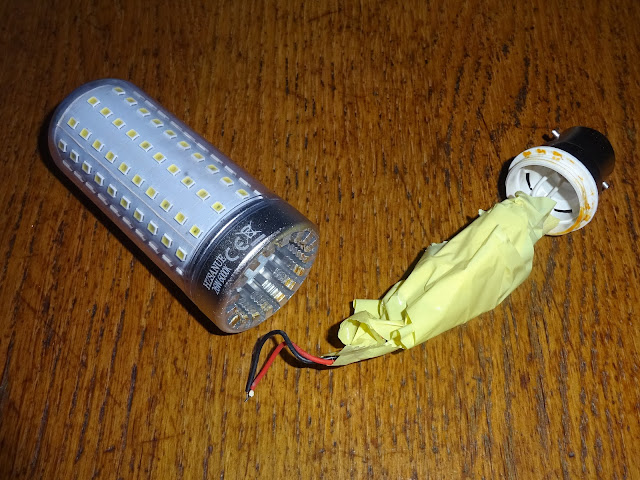

Out of curiosity, I decided to have a go at taking the dead one apart.

(I might have taken pictures at the time, but I can't find them now, so this is another one I took apart later.)

I cut into metal bayonet cap, but realised afterwards that it would have actually unscrewed.

And within, was something wrapped in yellow tape.

And there were the capacitors that were probably the issue.

There didn't seem any point in fixing that as the bayonet cap was mangled, but I ordered some replacements (2.2µF 400V and 6.8µF 400V) and eagerly awaited the next one failing.

A month or two later, the second one failed, and I much more carefully attempted to unscrew the cap, and got it off in one piece.

I replaced the failed electrolytic caps, taped it back up, screwed it back together and it worked, so put it back into the pile to use next time, and I still had one more new one.

Much time passed, and after another year, two more had failed, and I replaced those with the other new one and the repaired one.

Another year or so passed, and about a month ago, one more failed, but it was the one facing away from the desk where I worked, so I just left that as I was busy with other things.

Finally, the last of the new ones went, leaving only the one I had repaired, so time to repair the rest.

I started with the two recent failed ones (as I had yet to find the two which had failed about 2 years ago).

The first one I opened was not a good start, the wires fell off the LEDs.

They were soldered all the way at the top.

Little change of getting the wires back in those holes, and also no way to solder from the top.

I did not look like the clear plastic cover would come off. Later on, I did try cutting a hole in it, but the board was damaged where the wires had come off.

When I unwrapped the board, the wrapping was flaking off the capacitors and came away with the yellow tape.

Maybe I will have better luck with the second one?

This is not going well is it? There is also something else wrong that you can just see on this picture

On both of these, the wrapping had started to come off the capacitors, but I was able to read the values from the remnants and they were the same as the previous one.

I tested those and found the values all low (2.14µF for a 6.8µF cap), but the ESR was off the scale. >20Ω not seen that before.

I fitted the replacements to one, but when I was checking it over, I noticed the IC.

Bang. That doesn't look good. Big hole in the chip.

Oh well. Never mind, I have the board from the one where the LED connection broke.......

Oh dear, that has gone bang as well, and also seems to have a hole in the current sense resistor.

Zero out of two. Not a great start.

Later on, I found the other two bulbs that had failed a couple of years ago.

I wonder if those will be any better?

I carefully unscrewed and unwrapped those.

The capacitors looked in better condition here, with the wrappings intact.

The other one seemed a slightly different design with a pair of current sense resistors in parallel.

The driver chips looked intact, so I removed the caps.

These were a little better, but still off the scale on ESR.

Looking at the pile of dead caps now, I see that the larger caps were all 6.8µF 400V, the smaller ones were not all the same, I have one 1µF 400V, one 3.3µF 250V and the reset were 2.2µF 400V.

The replacement 3.3µF would have had too wide a lead pitch, so I went for the 2.2µF 400V for the smaller caps and 6.8µF 400V for the larger ones.

I used some nice Nichicons. These are 105C rated for 10,000 hours (that's about 2 years at 18 hours a day).

The larger cap is mounted with the leads bent. I tried to raise it up away from the IC to match the height of the other cap.

I rewrapped those in capton tape and closed them back up.

I did think about using glue or threadlock, but they seem to lock well enough and can be fitted and removed from the holders without unscrewing.

I tested those and both worked, so I put those back in service.

Not bad, two out of four this time, that's a 50% success rate. I might be able to resurrect one more of them if I get some replacement chips.

"and the other one"

Sorry?

"remember the first one"

Oh, OK, good point, I fixed that, so that's actually three out of five. 60% success rate. Better.

"no, the actual first one."

Oh, great, the one I couldn't fix because I cut the cap off. Now we're back to three out of six. 50% success rate. You're not really helping here.

"yeah but the board on that one...."

Oh yeah, thank you for reminding me.

I searched around and found the bits of that. The LED section was fine, and the chip on the board was intact. I replaced the capacitors and wired that to the bayonet cap from the one with the blown chip and snapped LED wires.

OK, better, that's now four out of six. I would like to see anyone repair incandescent bulbs like that.

I wrote the date on for reference, so I knew which ones were which.

Those should last me another couple of years.

I did actually order another set of these yesterday, since I know I can keep them running and I like the style.

There seemed to be quite a variation in the design.

I noticed on that last one that it appeared to be missing the flyback diode

I did think about stealing one from the other board, but the BP2861 datasheet I looked up didn't show it as being required, and it appears to work fine without.

The ones with the blown chips both had those diodes, so it is not as though they had helped.

They have followed that reference design, but have used a wirewound resistor on the "live" input (it could be live or neutral, depends which way you put the bulb in the holder).

They have also added a mov across the input.

The transformer on there is being used as an inductor, so winding insulation is not an issue as it would be with something like a 5V USB supply.

The metal case of the bulb is not earthed, no surprise there. It is isolated by the screw on part of the base.

It shouldn't be in contact with anything. If the insulated wrapping were to break down, it might end up live, but you wouldn't be anywhere near touching it unless you were reaching to the far back of the bulb holder and had left the light switched on.

Worse case the wrapping would break down and it would short in two separate places, that should cause the fusible resistor to blow (assuming it is actually fusible....), and very worse case would trip the lighting RCD.

Either way, it seems these should be OK to keep using. Nothing in there that would make me nervous to reuse them. (but obviously, use common sense, don't follow my advice on anything like this, consult a qualified electrician and only buy quality bulbs from a reputable supplier).

I noticed some were missing the R1 resistor to pin 2, which is shown as not connected on the BP2861, but does appear in the datasheet for the BP2866 which some of the other boards have.

None of these datasheets seem to have suggested value or any information about how to calculate them.

There were also some boards had two current sense resistors in parallel.

There is no consistency, it seems like they just grabbed whatever looked about the right sort of thing and jammed it in there. That's just the way these things are unfortunately.

At some point in the future when this round of replacement caps have failed, or more chips have blown, I will do another batch of repairs.

In the mean time, I have three bulbs in use, one spare repaired unit and an assortment of spare parts.

- One good LED module

- One LED module with broken connections

- Two controller boards with blown chips

- One slightly mangled bayonet cap

The Bright Power (or Bright Power clone) chips they use is the sort of thing you can find on ebay and Ali express, but not at Digi-Key or RS or anywhere like that. I suppose I could order some chips and they would probably work again.

I would be tempted to design a new PCB that would slot into the case better, I could mount the caps closer to the top which is facing down the way I have them mounted, so should be a little less hot.

I would need to find a suitable driver chip from a reputable manufacturer with a properly specified datasheet, but there seem to be an ever increasing number of options there.

Advertisements

I normally work on old computers, or new things for old computers, such as these:

ZX80, ZX81, Commodore PET and Jupiter Ace compatible computer kits

https://www.tindie.com/stores/tynemouth/

Patreon

You can support me via Patreon, and get access to advance previews of blog posts and behind the scenes updates. This also includes access to my Patreon only Discord server for even more regular updates.